Enhancing Efficiency: CNC Machining for Cast Iron Parts

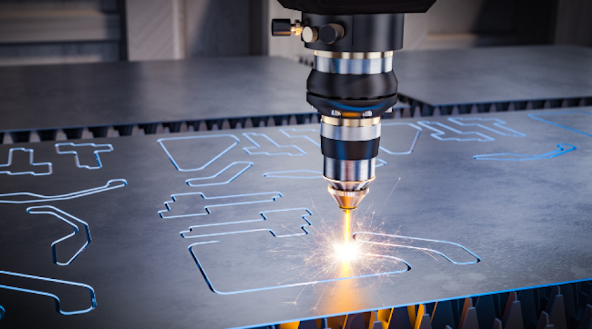

In modern manufacturing, efficiency, and precision are paramount to staying competitive. When working with cast iron materials, CNC machining emerges as a game-changer. Computer Numerical Control (CNC) technology has revolutionized how cast iron parts are manufactured, offering many benefits that traditional machining methods cannot match. In this article, we will delve into CNC machining for cast iron parts, exploring its advantages, techniques, and role in enhancing overall efficiency. Join us as we unlock the secrets to maximizing productivity and quality in cast iron machining.

Understanding the Power of CNC Machining

What is CNC Machining?

Before we dive deeper, let's understand the basics. CNC machining is an advanced manufacturing process that uses computer software programs to control the movement of machining tools. This level of automation allows for precise and repeatable operations, making it ideal for complex cast iron components.

Advantages of CNC Machining for Cast Iron Parts

CNC machining offers several advantages that make it the go-to choice for machining cast iron parts:

High Precision:

CNC machines can achieve remarkable precision, even with intricate designs and tight tolerances required in cast iron parts.

Consistency:

With CNC programming, each cast iron part is reproduced identically, ensuring consistent quality throughout production.

Reduced Labor Costs:

Automation in CNC machining minimizes manual labor expenses, leading to cost savings in the long run.

Flexibility:

CNC machines can handle various cast iron parts without tool changes, from simple to complex geometries.

Shorter Lead Times:

CNC machining significantly reduces production lead times, helping manufacturers meet tight deadlines.

Techniques and Best Practices in CNC Machining for Cast Iron Parts

CNC machining for cast iron parts requires a deep understanding of the material's properties and the intricacies of the machining process. Implementing the proper techniques and best practices can significantly improve the machining operations' quality, efficiency, and cost-effectiveness. Let's explore some additional techniques and best practices to enhance further the CNC machining process for cast iron parts:

Tool Selection and Toolpath Optimization

Choosing the proper cutting tools is crucial in CNC machining for cast iron parts. More complex materials require tools with excellent wear resistance. Carbide inserts and coated tools are often preferred for their durability and longevity. Optimizing toolpaths can enhance efficiency by reducing cutting time and minimizing tool wear.

High-Speed Machining (HSM)

High-Speed Machining (HSM) is a technique that maximizes cutting speeds while maintaining precision. When applied to cast iron machining, HSM can significantly reduce cycle times, resulting in faster production and improved efficiency.

Coolant Strategies for Cast Iron Machining

Coolant is vital in maintaining tool temperature and preventing overheating during cast iron machining. Proper coolant application can prolong tool life and ensure consistent surface finishes in cast iron parts.

Trochoidal Milling

Trochoidal milling is a popular technique used in CNC machining for cast iron parts, especially in roughing operations. It involves using a circular toolpath with high-speed rotations and constant chip load. This approach reduces tool wear, dissipates heat effectively, and improves material removal rates, resulting in faster machining times and extended tool life.

Adaptive Machining

Adaptive machining is an innovative CNC technique that adjusts cutting parameters in real-time based on the conditions encountered during the machining process. It optimizes feed rates, depths of cut, and cutting speeds to adapt to variations in material hardness and tool wear. Adaptive machining in cast iron can enhance surface finishes and ensure consistent quality throughout the production run.

Vibration Damping Solutions

Machining cast iron parts can generate significant vibrations that may impact surface finishes and tool life. Implementing vibration-damping solutions, such as tuned mass dampers or vibration-absorbing tool holders, can stabilize the machining process and reduce vibrations, resulting in improved surface finishes and dimensional accuracy.

Using Multi-Tasking CNC Machines

Multi-tasking CNC machines, also known as mill-turn machines, combine milling, turning, and other machining processes in a single setup. Multi-tasking machines can streamline production, minimize setups, and reduce cycle times for cast iron parts with complex geometries or features requiring multiple machining operations.

Heat Control in Machining

Cast iron is hailed for its excellent heat retention properties, which can affect the machining process. Controlling the heat generated during machining is crucial to prevent thermal distortion and ensure dimensional accuracy. Techniques like high-pressure coolant delivery and strategic toolpath planning can effectively manage heat in cast iron machining.

Fuyuancasting

Fuyuancasting is a leading manufacturer and supplier of CNC machines and metal parts. Our cast iron parts are renowned in the marketplace for their durability, precision, and seamless finishes. Place your order with the trusted Cast Iron Machining parts manufacturer to get these fantastic parts at affordable rates.

FAQs

Q> Is CNC machining suitable for all types of cast iron materials?

Yes, CNC machining can handle various types of cast iron, including gray cast iron, ductile iron, and malleable iron, with exceptional precision and efficiency.

Q. Can CNC machining achieve tight tolerances in cast iron parts?

Absolutely! CNC machines are known for achieving tight tolerances, ensuring high precision in cast iron machining.

Q. How does CNC machining compare to traditional machining for cast iron parts?

CNC machining offers higher precision, repeatability, and efficiency than traditional machining methods, making it the preferred choice for many manufacturers.

.png)

Comments

Post a Comment